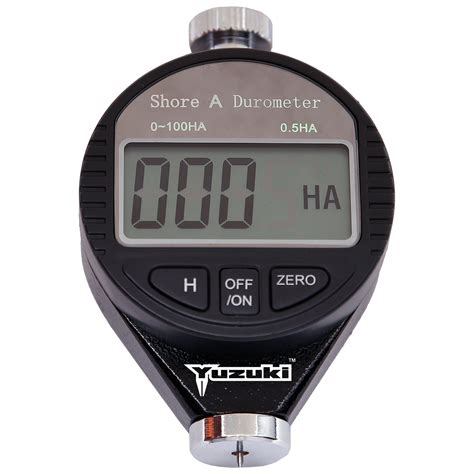

a common hardness test for plastics and elastomers is|plastic hardness chart : Chinese Measuring Shore hardness is a widely used technique for assessing the hardness of materials such as rubber, plastics, and elastomers.Unlike other hardness testing methods like Rockwell or Brinell, which are designed for metals and harder materials, Shore hardness testing specifically measures the resistance of more flexible materials to indentation.

Cassino Betsson poker grátis, roleta, Blackjack e bingo ⭐ b.

{plog:ftitle_list}

Top Pornstars - TW Pornstars - Top pornstar videos and pics

rubber hardness test

This chapter reviews the tests and procedures used for measuring hardness of plastics and elastomers. The conventional testing methods (Rockwell, Vickers, Brinell, and Knoop) used for testing of metals are based on the idea that hardness represents the resistance against .Durometer is a self-referencing scale that compares the hardness of a particular group of materials: elastomers and plastics. There are a number of durometer or Shore durometer scales but Shore A and Shore D are by far the most useful .

ISO 2039-2 and ASTM D785 define various Rockwell hardness scales for plastics testing. In contrast to ball indention hardness, in which the indention depth is measured under load, with the Rockwell method, the indention depth .

compression test 2008 ktm 530

To test for durometer hardness, an engineer places the needle against the elastomer or plastic and applies pressure. . universal, and reproducible reference. The three most common shore hardness scales are .The standard describes hardness testing methods on plastics and elastomers. It gives a most clear and complete compilation of test procedures and thus facilitating the selection of a suitable test method. Essential information about the common test procedures are summarised in graphs and tables. The standard is complemented by information on applicable standards and . Measuring Shore hardness is a widely used technique for assessing the hardness of materials such as rubber, plastics, and elastomers.Unlike other hardness testing methods like Rockwell or Brinell, which are designed for metals and harder materials, Shore hardness testing specifically measures the resistance of more flexible materials to indentation. The Rockwell hardness tests harder materials like polycarbonate, polystyrene, and polyamide.. On the other hand, the Shore method is used for testing elastomers, rubbers, and softer materials like polypropylene, polyethylene, polyvinyl chloride, etc.. The Rockwell Hardness method begins with a sample with at least 6.35 mm smacked by a hard steel ball.

TPEs can also be made from post-consumer recycling like ocean plastic (e.g., fishing nets) and turned into material for other goods. Most thermoplastic elastomer products are also recyclable under Plastic Recycling Code 7. Lightweighting. Thermoplastic elastomers are also used to make products more lightweight.The Shore (Durometer) test is the preferred hardness testing method for elastomers and is also commonly used for compliant plastics such as polyolefins, fluoropolymers, and vinyl polymers. Shore hardness testing is typically performed following ASTM [19] standards. The two most common test procedures are the Shore A and the Shore D scales.

Elastomers can regain their original shape after deformation. This property is characterized by the Young's modulus \(Y\), which is the ratio of tensile stress \(σ\) to tensile strain \(ε\) in the linear elasticity regime of a uniaxial deformation. Impact Resistance: Elastomers can withstand high levels of strain without rupturing.The followings are the most common hardness test methods used in today`s technology: Rockwell hardness test Brinell hardness Vickers Knoop hardness Shore 3.1. Rockwell Hardness Test. The Rockwell Hardness test is a hardness measurement based on the net increase in depth of impression as a load is applied.

Hardness testing within the realm of materials testing. Today, hardness testing is one of the most widely used methods in mechanical materials testing, especially for metals. On the one hand, this test method can be used to find qualitative relations to other material properties (e.g., strength, stiffness, density) or to the material behavior under certain stresses (e.g., abrasion .Common Standards for Hardness Properties Testing. ISO 48— Rubber, vulcanized or thermoplastic -- Determination of hardness -- Part 2: Hardness between 10 IRHD and 100 IRHD; BS ISO 48-4 Rubber, vulcanized or thermoplastic. Determination of hardness. Indentation hardness by durometer method (Shore hardness) BS EN ISO 868 Plastics and ebonite. Toxicity depends on the exact chemical composition. Some TPEs use polyurethane or other common plastics are considered non-hazardous materials. Processed TPEs do not release toxic compounds during typical lifecycles. Risks come from overheating or burning which releases gases from decomposition.The selection of the appropriate measuring method depends primarily on the type of material and the geometry of the test specimen and is also determined by the degree of hardness to be expected. For hardness testing of elastomers and thermoplastic elastomers, depending on the basic hardness and geometry of the test specimen, the hardness .

Many apply a load and measure the depth or size of the resulting indentation. Hardness can be measured on the macro-, micro- or nano- scale. 1.2. Brinell Hardness Test: The oldest of the hardness testing methods in common use on engineering materials today is the Brinell hardness test, invented by Dr. J. A. Brinell in Sweden in 1900. The .Learn how Shore D Hardness test work, its significance to determine hardness of the material as well as what are common polymers this test is used for. The material selection platform . For rubbers, elastomers & softer plastics, Shore Hardness is often preferred. Very soft materials can be measured using Shore A hardness.

PP, HDPE, ABS/PMMA, and PS were chosen as representative plastics. The test conditions are shown in Table 3, and Fig. 2 shows the appearance of the DUH-210 Dynamic Ultra Micro Hardness Tester for .

Hardness Test As Per Standard ASTM D2240 Mastering Material Hardness: An In-Depth Look at ASTM D2240 Testing Introduction Material hardness is a key property that influences a material’s resistance to deformation, wear, and tear. . ASTM D2240 provides a standardized method for measuring the hardness of rubber, elastomers, and plastics .

• Rockwell tests cover a wide range of metallic materials, while Shore testing is for plastics and elastomers. Resources: Ellis & Associates CADD/Technical IllustrationTesting of Plastics, Elastomers, Composites and Film Intertek tests plastic and polymer materials to Standard Test Methods for the quality and assessment of plastics and polymeric materials. Intertek Plastics Technology Laboratories (Intertek PTL) is an independent laboratory dedicated to fast-turnaround of plastics, elastomers, composites & fi lmassessed after removal of the indenter on the basis of the permanent plastic deformation. In the case of elastomers, most of which exhibit elastic behavior, the indentation depth of the indenter is measured during the test.1 The most common method for testing vulcanized elastomer compounds and articles is Shore A hardness (see Fig. 1).The oldest of the hardness test methods in common use on engineering materials today is the Brinell hardness test. Dr. J. A. Brinell invented the Brinell test in Sweden in 1900. . A Durometer is an instrument that is commonly used for measuring the indentation hardness of rubbers/elastomers and soft plastics such as polyolefin, fluoropolymer .

Thermoplastic elastomers (TPEs) are unique materials that combine the elastic properties of rubber with processability. menu. . They can be melted and reshaped like traditional plastics, allowing for efficient recycling. . Manufacturers offer a limited availability of low hardness TPEs, and processing requires prior drying. Despite these . This publication provides, based on the state of standardization, an overview of the hardness testing of metals, plastics, rubber and other materials. . Hardness Measurement of Plastics and Elastomers $25.00 6. Instrumented Indentation Test $25.00 7. Standardization $25.00. Add to Cart. Standards & Publications. SAE MOBILUS; By using these scales, individuals can have a common reference point when evaluating and discussing the hardness properties of different materials. . Hardness testing plays a significant role in failure analysis investigations. . The scales are used to measure the hardness of materials, particularly elastomers, rubbers, and plastics. There .

Properties of Elastomers. The properties of elastomers play a pivotal role in determining their suitability for various applications. Here are some properties serving as critical metrics in assessing their performance: [1-3] Hardness. Hardness indicates an elastomer’s resistance to indentation or deformation under applied pressure.In addition, creep testing and dynamic mechanical analyses of viscoelastic plastics are briefly described. The discussion covers the most commonly used tests for impact performance, various types of hardness test for plastics, the fatigue strength of viscoelastic materials, and the tension testing of elastomers and fibers.

Thermoplastic Elastomers (TPEs) are a broad family of polymers that melt when heated and harden when cooled, exhibiting characteristics of both plastics and elastomers. They are copolymers, typically composed of plastic and rubber, which consist of materials with both thermoplastic (hard) and elastomeric (soft) properties. The resilience of rubbers and plastics means that the indentation reading may change over time, so the indentation time is sometimes reported alongside the hardness number. The results obtained from a Shore Durometer hardness test are a useful measure of the relative resistance to indentation of various grades of polymers.

compression test 2008 ktm 539

Resultado da Mais Relevante Free Gloryhole Swallow Videos from De Sempre. The best Gloryhole Swallow porn movies are on Redtube.

a common hardness test for plastics and elastomers is|plastic hardness chart